CU-Ag

Silver-bearing coppers : Increasing additions of silver give increase in creep strength and resistance to softening in elevated service temperatures.

Overview

Silver-bearing coppers : Increasing additions of silver give increase in creep strength and resistance to softening in elevated service temperatures. Good creep resistance to 250 oC (short times at 350 oC ) provides suitability for electrical motor parts, semiconductor components and etching plates.

To meet requirement of customers, the additional small amount of silver in copper improves the resistance to softening of materials. Most applications for this material are commutator bars and segment in traction motor and various industrial DC motors.

|

Type of copper

|

Designation

|

Standard

|

Alloy NO.

|

Thermal conductivity (W/m.K)

|

Electrical conductivity (%IACS)(A)

|

||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Silver bearing tough pitch |

|

|

|

388 |

|

||||||||||||||||||||||||||||||||||||||||

|

Oxygen-free, silver bearing |

|

|

|

388 |

98.3 |

||||||||||||||||||||||||||||||||||||||||

|

Phosphorus deoxidised, silver bearing |

|

|

|

|

96.6 |

** Mechanical property are follow by internal specification and customer requirement.

Chemical Composition

|

UNS No.

|

Chemical Composition : Phosphorus-deoxidized copper

|

|---|---|

|

C11300 |

99.90 Cu 0.04 O 0.025 Ag |

|

C11400 |

99.90 Cu 0.04 O 0.031 Ag |

|

C11500 |

99.90 Cu 0.04 O 0.050 Ag |

|

C11600 |

99.90 Cu 0.04 O 0.078 Ag |

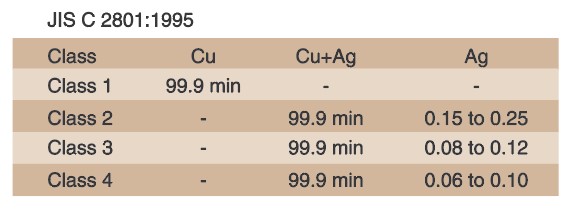

Specifications of commutator bars / segment

- IEC 60356

- BS 1434 : 1985

- JIS C 2801 : 1995

Chemical Composition (%)

Let us know how we can help you. Our team is ready to discuss your business needs and answer any questions you may have.

Explore Other Market Solutions